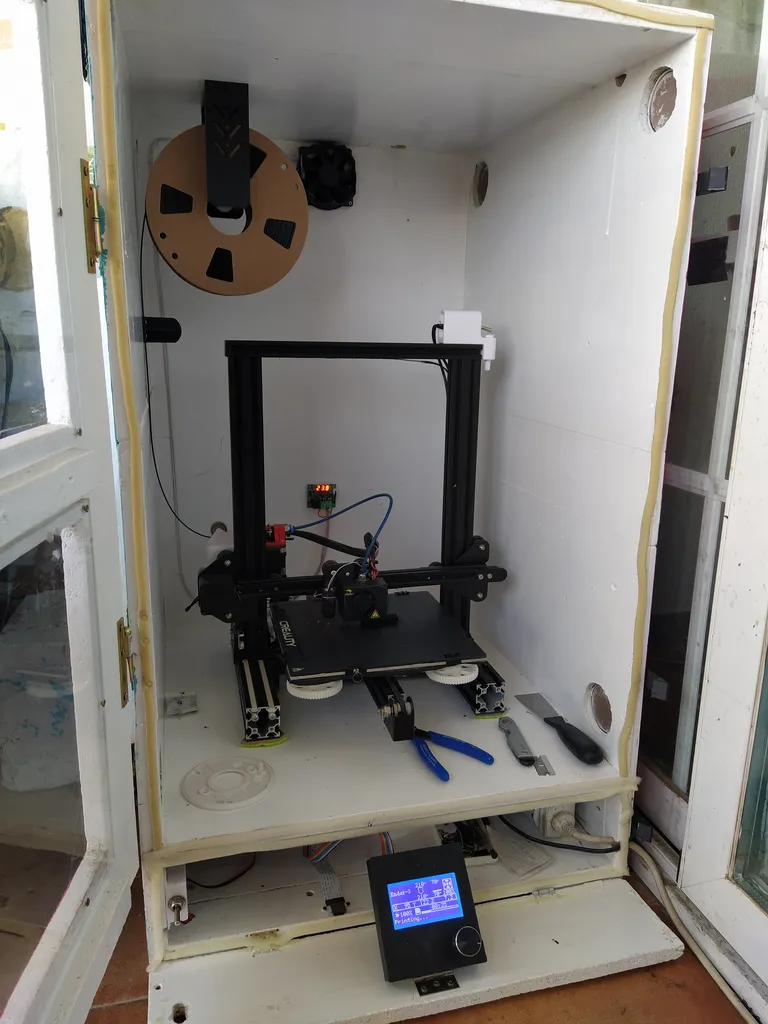

The ultimate quest to make the Ender 3 silent has come to its conclusions by casting the printer outside of the home into its own enclosure

Unfortunately, there weren’t many big enough boards lying around so there need a bit of a workaround but it turned out just as good.

. No more spending on silent motherboards or splashing out on Noctua fans.

In hindsight, the white isn’t the perfect color for an outside cabinet.

It’s ready to work but far from finished.

Placing the motherboard into a different compartment to shield it from the printing heat seemed like a great idea but the factory cables don’t really allow much wiggle room when it comes to connecting or disconnecting stuff.

A switch for the lights.

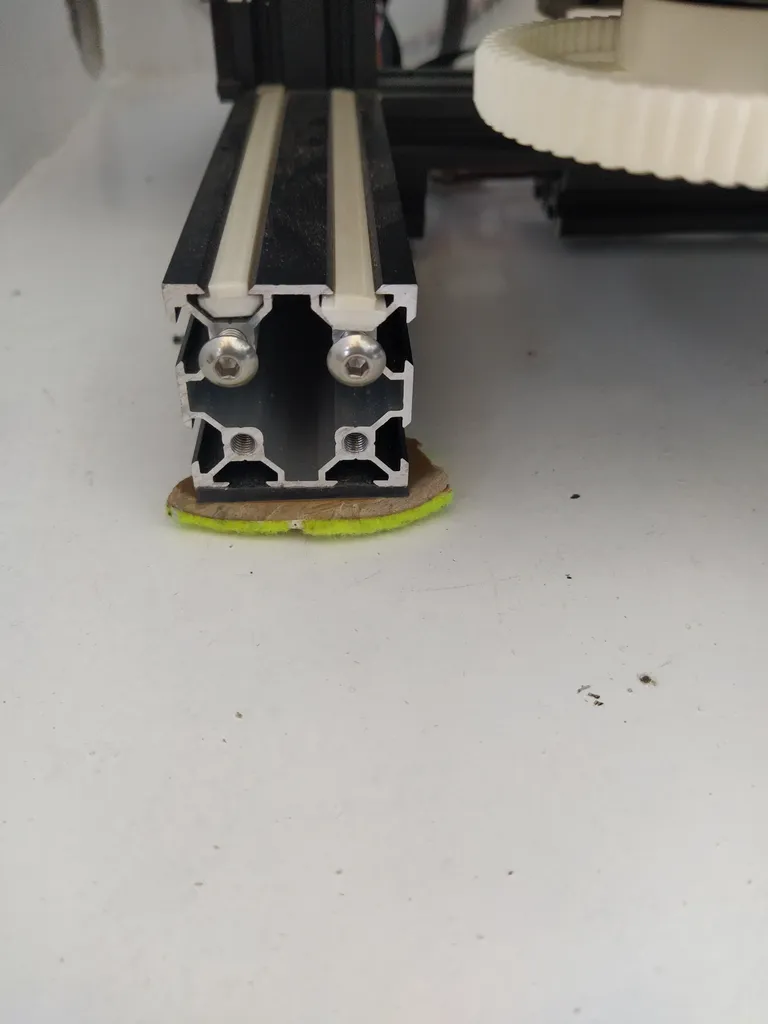

Building a completely sealed box seemed like a good idea but 3d printing with PLA needs cool air and that needs vent holes. To keep dust out as much as possible, parts of an unwanted thigh is used.

The vent holes weren’t enough on their own so a fan with a thermoswich was installed to keep the air moving when it’s necessary.

The original spool holder worked just fine but why not make another one.

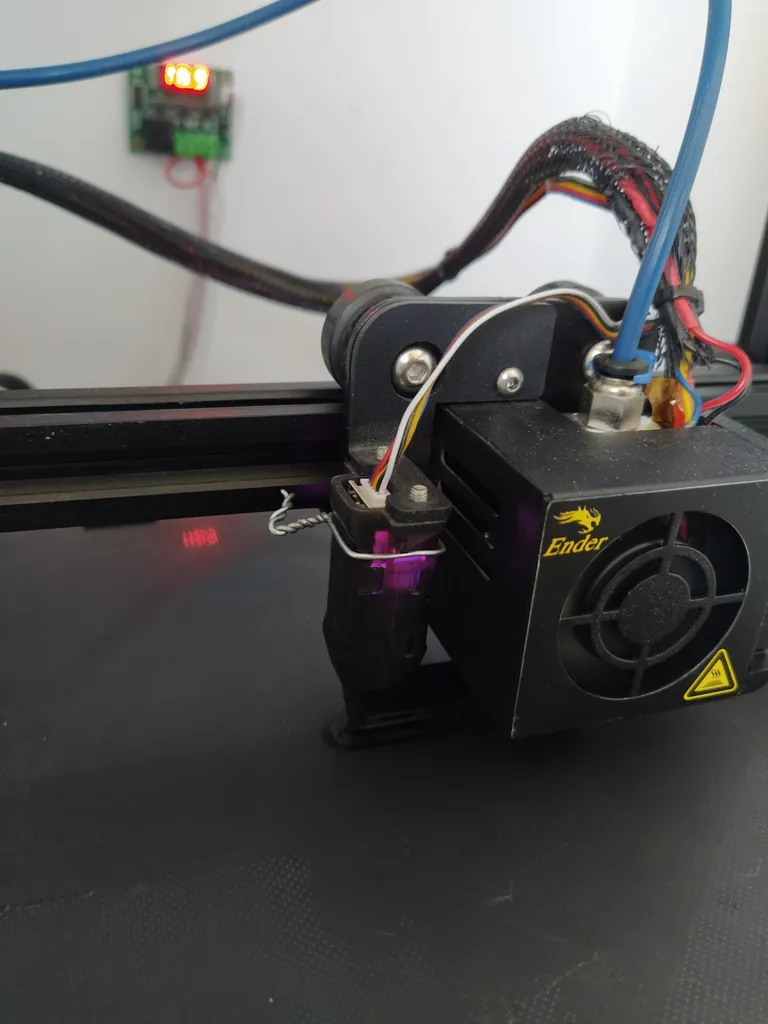

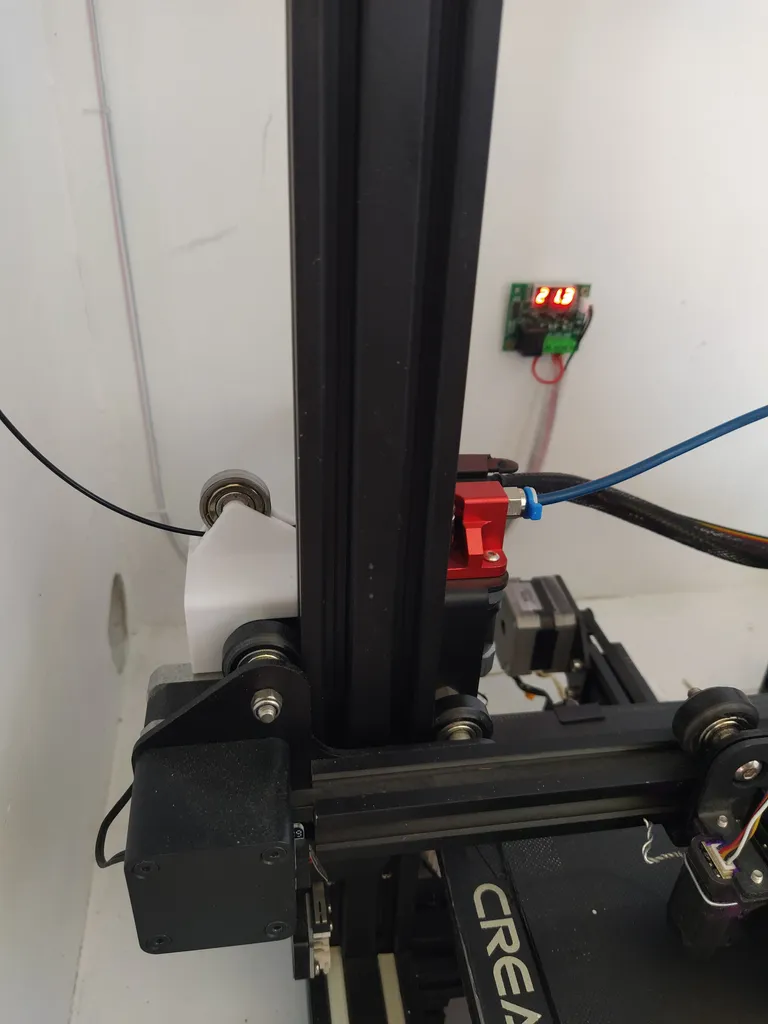

Filament runout switch made from a microswitch, roller blade bearing and 3d printed case.

End switch that switches off the 3d printer when the print job is finished. Very handy stuff.

Tennis balls are the best to absorb vibrations and make the printer box less noisy.

Yeah, that’s not nice but the latest Ender3 firmware is not really calibrated for the printbed…